|

Jussi Puranen

Permanent magnet machines – greater efficiency, reliability and flexibility for ships

Permanent magnet (PM) machines have been utilized with great success and satisfaction in numerous fields to date, including distributed power generation, elevators and hybrid cars. However, in the maritime industry, the shift from traditional technology in power generation has been slower due to skepticism within the industry. Read on to find out what immense benefits PM generators bring to ships compared to traditional technologies.

Development of electric power generation in ships

Electric power generation in ships has usually been conducted by separate auxiliary gensets or shaft generators connected to the main engine, either directly or through a gearbox. The auxiliary genset’s positive side is that it doesn’t require power electronics for frequency conversion when driven in constant-speed mode. However, the auxiliary gensets have higher specific fuel-oil consumption compared to the main engine, and they can’t run with cheaper heavy fuel oil (HFO) without additional equipment. Plus, they need more maintenance.

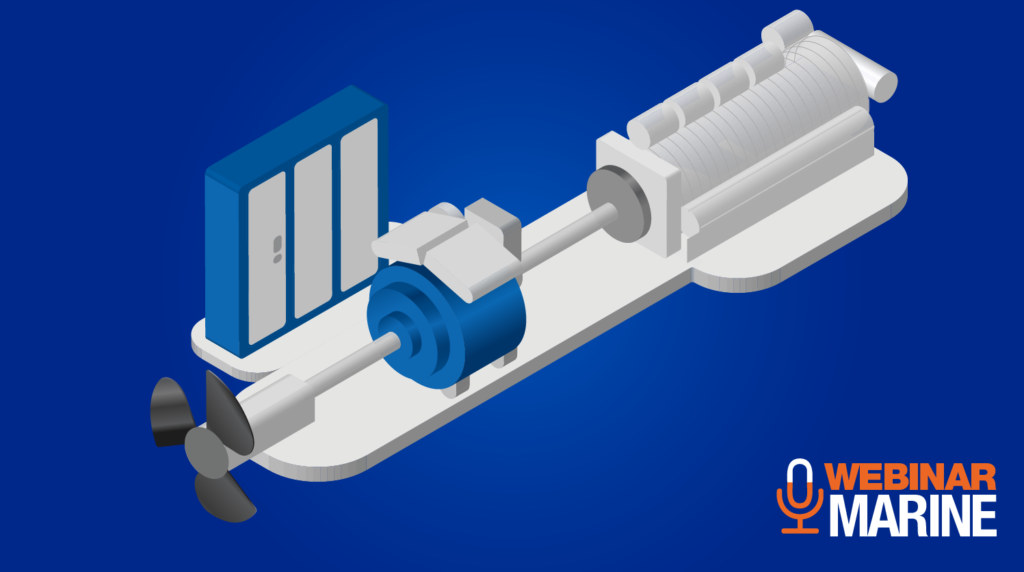

Shaft generators, which have typically been electrically excited synchronous generators (EESG), have been one option. Here, the shaft generator system consists of the EESG, which is mechanically connected to the main shaft and electrically connected to the ship’s grid – either through a frequency converter or directly, in which case only fixed speed is possible. The EESG system is rather complex, requiring additional equipment such as a brushless exciter – or slip rings – and an automatic voltage regulator (AVR). Most importantly, it has lower efficiency due to losses in the rotor winding. They are also physically large and have high rotating inertia.

PM shaft generator system – how does it help?

One of the most promising solutions is to replace the direct-driven electrically excited generator with a permanent magnet generator (PMG). The PM shaft generator provides three main benefits over the traditional technology.

The PMG has typically 2–3% higher efficiency throughout the entire operating range, reducing fuel oil consumption and emissions. This is explained by the fact that the PMG does not need additional energy for magnetization. When the fuel burned in the main engine to produce electricity in shaft generators often makes up more than 95% of overall lifetime costs, such a difference in efficiency leads to huge lifetime savings.

Secondly, the PMG is much simpler in terms of mechanical construction, resulting in greater reliability. It requires no additional equipment, such as a slip-ring unit or AVR that require maintenance and pose a risk of failure.

The third benefit is extremely low inertia and weight. This is related to the simple rotor construction. The EESG rotor is constructed of a solid-steel rotor with massive field poles and windings attached. In comparison, the PMG rotor is, in fact, a hollow steel cylinder with magnets fixed on its surface. These features have direct positive effects on the dynamic performance of the whole shaft line, including torsional vibrations and design flexibility for the ship.

To find out more on the technology behind these benefits, please read a more detailed explanation of PM machines in direct-driven shaft generator systems.

Frequency converters boost efficiency

Coupling a PM shaft generator with a frequency converter from The Switch seamlessly gives the maximum amount of freedom in optimizing the engine and propeller efficiencies. Variable-speed operation combined with controllable-pitch propeller – the so-called combinator mode – results in the best overall efficiency since efficiency of both the main engine and propeller can be optimized separately depending on load conditions. This also helps in meeting the tightening emission regulations, such as IMO Tier III.

Yaskawa Environmental Energy / The Switch keeps setting the pace

Yaskawa Environmental Energy has designed and manufactured over 80 direct-drive shaft generators for various speed and power ratings for various vessel types, such as product tankers, car carriers and LNG/LPG carriers. Acceptance from certification agencies has been positive, and several machines are already in operation. Since power demands from customers keep increasing, we have designed new shaft generator frame sizes that can go beyond 5 MW in power.

Yaskawa Environmental Energy / The Switch has also set up a world-class testing facility for electrical drive trains in Lappeenranta, Finland, with a capacity of 15 MW.

Please feel free to get in touch with us to discuss your particular needs.

About the author

Jussi Puranen

Head of Product Line – Electric Machines

at Yaskawa Environmental Energy / The Switch, Finland

Jussi has nearly 2 decades of experience in R&D and product development of electrical machines, and his main responsibilities are the product management and R&D of electric machines (especially PM machines). Puranen holds an M.Sc. (Technology) degree in Electrical Engineering and a D.Sc. (Technology) degree from the Lappeenranta University of Technology (LUT), Finland.