Think outside the gearbox with solid rotor technology

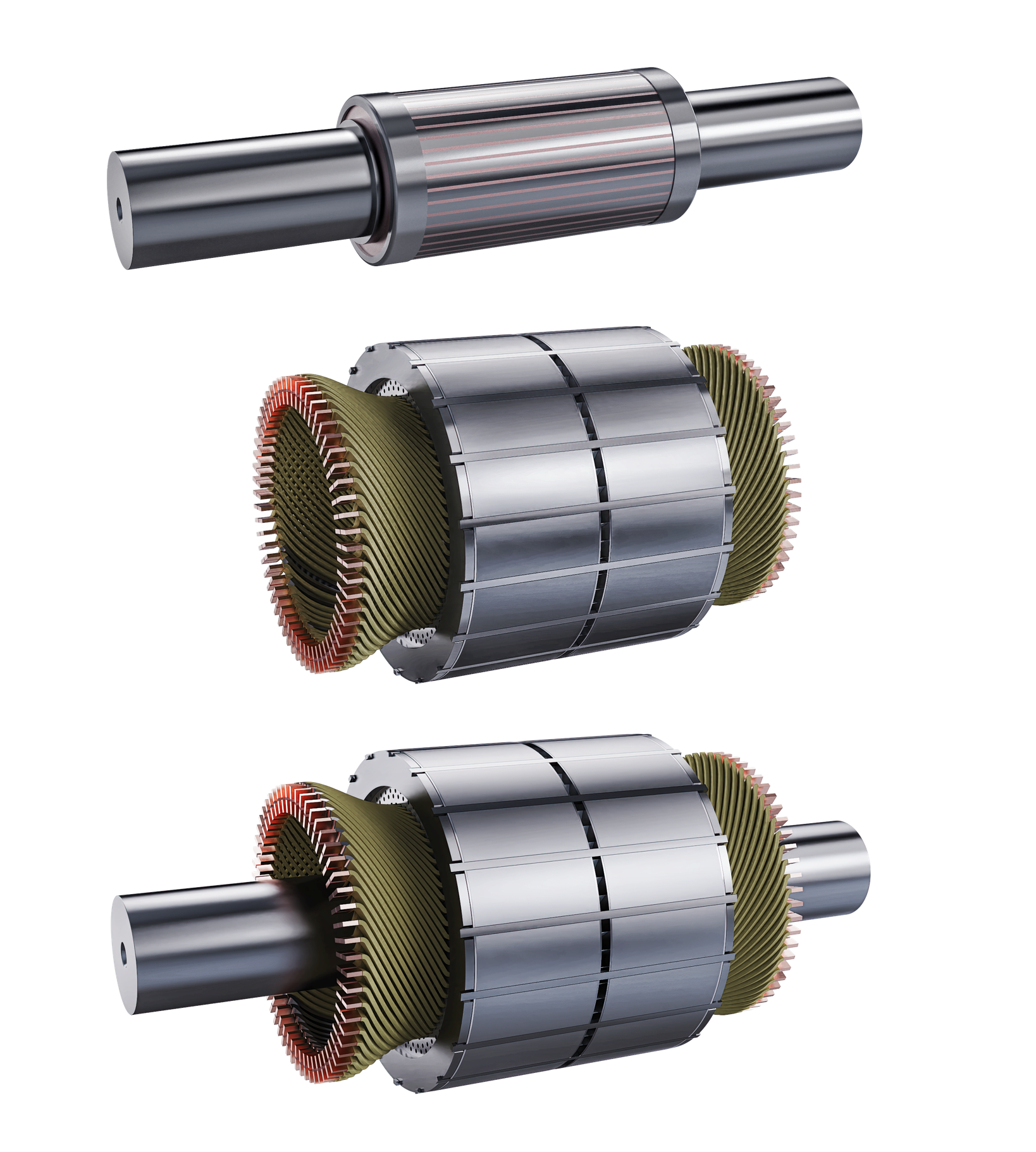

Our direct-drive, high-speed induction machines allow you to eliminate the mechanical gearbox, enabling you to reach higher speeds and unmatched energy efficiency.

Solid-rotor technology extends the speed capabilities of standard induction motors, answering the demand for high-speed motors when running below multi-megawatt powers.

0 rotor failures in over 10 years of industrial operation

Power range from 300kW to 2MW

Speeds up to 20,000 rpm

Our high-speed products are ideal for blowers, compressors, pumps, vacuum systems and other industrial applications in the speed range of 6,000 – 20,000 rpm. Additionally, our customers have used these motors in various test-bench configurations. We are also open to discussing projects involving multi-megawatt hermetically sealed and hydrogen compressors.

Recommended content

High-speed induction machines

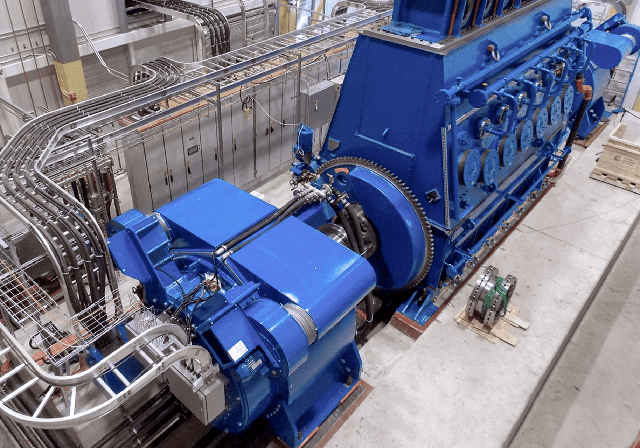

Our standalone product range comes in two frame sizes – 315 and 400. These high-speed machines are designed to be coupled to driving or driven machinery through a separate coupling, such as a steel pack coupling.

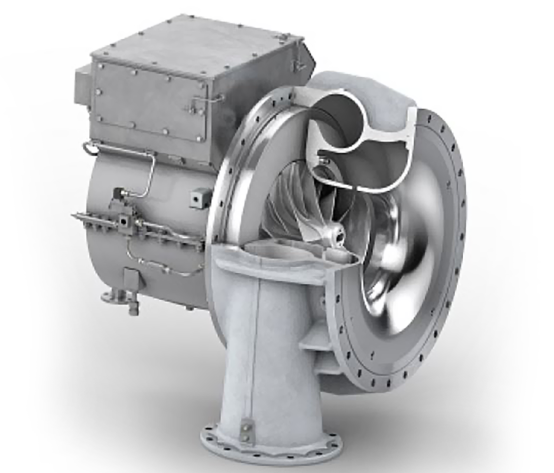

Semi-integrated solutions

Semi-integrated machines include the compressor, turbine or pump impeller mounted directly on the shaft of the electric machine. The bearing system and rotor dynamics are calculated and tailored to meet the specific application.

These solutions are available based on our successful long-term joint development projects with industry leaders. Ask us more!

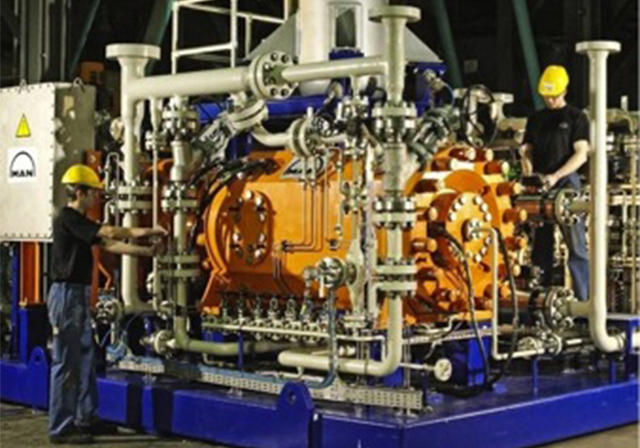

Fully integrated solutions

For ultimate system simplicity, we offer integrated machines. Active parts of the solid-rotor machine can be completely tailored to suit different applications. We are happy to discuss the delivery scope case by case.

These fully integrated solutions are backed by our successful joint development products with industry leaders.

Disruptive environmental energy solutions

When you need to convert, store or consume energy effectively and sustainably, our products provide an innovative solution. We are also involved in applications like permanent magnet (PMs) motors for mining and minerals and permanent magnet generators (PMs) for hydropower plants.

Exergy, Japan

Exergy, a startup from the University of Tokyo, signed a contract with The Switch in January 2019 to develop a frequency converter to match their proprietary-technology-based proton battery, which is used for a next-generation storage system.

SustainX, USA

US-based SustainX, a pioneer in isothermal compressed air energy storage (ICAES) technology, disrupted the current energy storage industry with its transformational cost competitiveness.

The Switch receives additional solid-rotor orders

In March 2025, The Switch secured a new order for 60 high-speed induction motors. This order is part of a long-term contract with the same customer and brings the total number of ordered motors to 250 of which nearly 150 have already been delivered.

Deliveries for this latest order will start at the end of 2025 or start of 2026. Approximately 4 to 5 motors will be supplied per month, totaling 40–60 units per year.

These feature a customized high-speed induction motor co-developed with the customer. The compact, semi-integrated high-speed design enables mounting directly on the application and is suitable for many other similar installations.

Another significant advantage of this design is its robust cooling system and ingress protection. The water-jacket cooling safeguards the motor against the high-temperature environment in which it operates, ensuring consistent and reliable performance.

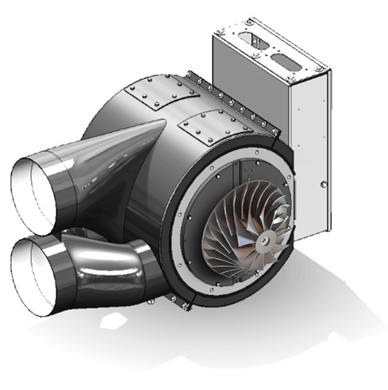

New blower for Tier III compliance

MAN Energy Solutions has launched its EGR (Exhaust Gas Recirculation) electrical turbo blower for the marine market. The Electrical Turbo Blower (ETB) units will be installed aboard vessels as part of their main engines’ integrated EGR system.

Gateway, USA

In 2012, The Switch made a significant CHP converter delivery to the Gateway building in White Plains, New York. Commissioning was carried out in early 2013. The installation featured 3 converters in parallel and included an HMI. This was the second 2 MW+ installation for The Switch in the New York area.

Yonkers, USA

Following on the success of the Gateway project, The Switch delivered another CHP converter to the Yonkers Waste Water Treatment plant. This innovative installation utilizes gas from the digester to create electrical power. The converter allows the plants to accurately control power production and meet grid interconnect requirements.

MAN Energy Systems

MAN Energy Systems, formerly MAN Turbo, chose our solid rotor technology for a high-power compressor of 8 MW, 10,000–12,000 rpm, for a gas application that survives subsea installation with aggressive gases.

SustainX, USA

US-based SustainX, a pioneer in isothermal compressed air energy storage (ICAES) technology, disrupted the current energy storage industry with its transformational cost competitiveness.

Gardner Denver Pulp & Paper

Gardner Denver Pulp & Paper, formerly Runtech of Finland, has placed continuous volume orders for high-speed motors and drives to be used in its paper machine vacuum systems that run at over 10,000 rpm. Learn how we helped them save energy, space, weight and water in their vacuum system.

FIMA, Germany

German FIMA Maschinenbau GmbH, our first chemical industry reference, ordered a series of 200 kW high-speed motors for turbo blowers with a speed of nearly 11,000 rpm.