With high-speed electrical motors, there is a clear gap between running applications below 200 kW with induction or permanent magnet machines and other applications developed in-house that run at multi-megawatt powers. This webinar, hosted by Turbomachinery International, takes a look at how solid-rotor technology extends the capabilities of standard induction electric motors to fill that gap.

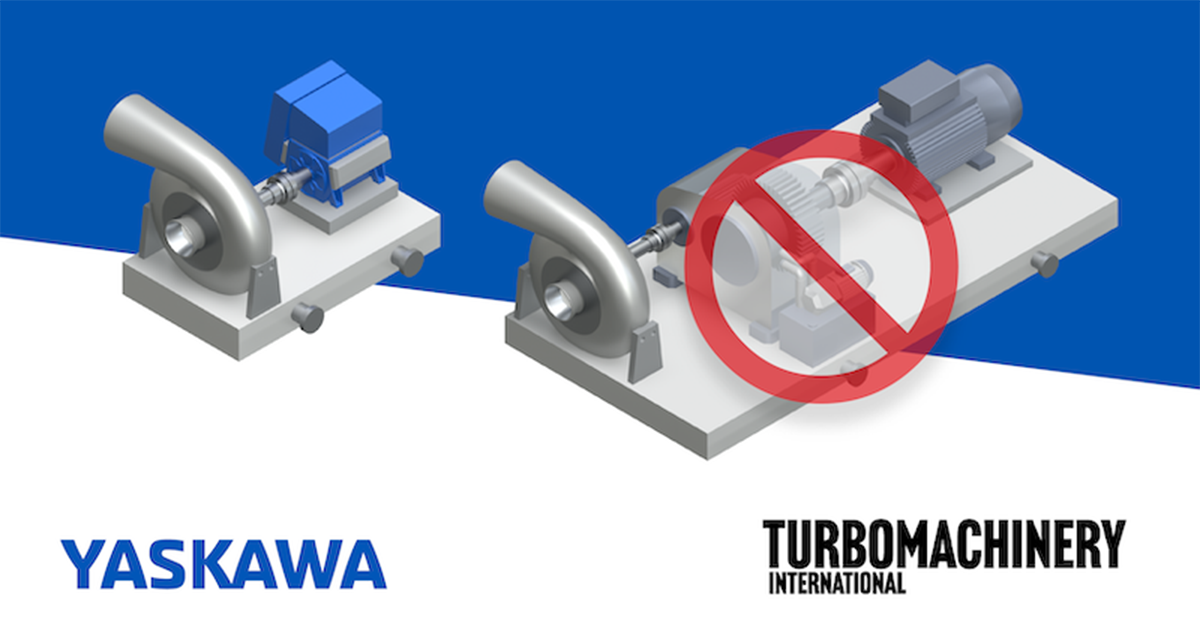

By pairing a high-speed solid rotor motor or generator with a 2Q or 4Q variable frequency drive (VFD), it is possible to run high-speed direct-drive applications more cost efficiently at higher powers and higher speeds. Applications that have benefited include retrofits, coupling radial turbine and compressors to electrical machines, as well as test bench systems.

Key learning objectives

- Availability of direct-drive gearless solutions using solid-rotor technology

- Key design elements to consider – torque-speed envelope, bearings, cooling, coupling, VFD

- What applications can benefit most?

Presenters:

Markus Silventoinen Product Manager, Solid-Rotor Machines Yaskawa Environmental Energy / The Switch |  Giulio Martorelli Business Development & Key Account Manager Yaskawa Environmental Energy / The Switch |  Mikko Lönnberg Head of Marketing and Business Development Yaskawa Environmental Energy / The Switch |

Moderator:

Drew Robb

Editor-in-Chief, Turbomachinery