Commissioning the permanent magnet (PM) machine for a marine vessel’s power distribution or propulsion system is the last – yet still crucial – step in a long, complex process. There’s no room for error and little tolerance for delays. Mechanical and electrical interfaces must match.

We at The Switch are invested in your vessel’s performance. We know the vessel and its crew’s safety will depend on the execution of every detail to the highest standards.

So how do we guarantee a positive commissioning result?

What ensures a successful outcome?

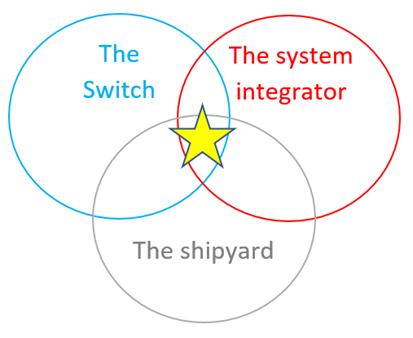

Success at commissioning requires the close interaction of three parties:

- The shipyard

- The system integrator

- The commissioning team from The Switch

But it doesn’t start there. Success depends on careful planning, communication, coordination and cooperation well in advance of the actual day.

- Technical specifications and installation instructions must be clear and shared early, with generous time allowed for questions, answers and any needed adjustments.

- The order of events must be discussed and defined, with any choices clearly resolved.

- All parties must clearly understand their responsibilities at each step and how to coordinate with others.

with the star indicating commissioning

We at The Switch draw up a detailed instruction plan before commissioning day.

What happens during marine PM machine commissioning?

Typically, marine PM machine installation and commissioning takes 1–2 working days and includes the following steps:

Phase I: Installation of the intermediate shaft in the PM machine

- At shipyard before the shaft generator is transferred to the vessel

- Heavy tools and cranes are needed when lifting massive components

Phase II: Installation of the generator into the vessel

- Loading the PM machine onto the frame and bolting the two together

- Running a jack-up test of the shaft line without the impact of the magnetic forces while the rotor is still disconnected (optional)

- Locking the rotor to the shaft with hydraulically tensioned stud bolts and locking the stator

- Making final adjustments for the eccentricity and air gap

- Running a jack-up test of the shaft line with the impact of the magnetic forces

- Installing shaft seals

Phase III: Commissioning

- Installing the encoder

- Closing the machine

- Taking insulation resistance measurements

- Checking auxiliary device(s)

- Making visual inspections

- Checking power cable connections

At this point, the machine is mechanically and electrically ready for sea trials.

Your success is our aim

A new vessel at a shipyard is often a chaotic environment, with much happening simultaneously on a strict timeline.

The Switch understands the potential for issues arising from such a complex and high-pressure situation. We make attention to detail a high priority. Your success is our aim.

Please feel free to get in touch if you have any questions or would like to know more about our commissioning process.

We are happy to answer any of your questions.

Senior Development Engineer

Simo Mattila

Simo works as Senior Development Engineer at The Switch. He has 15 years of experience in the mechanical engineering of electrical machines. During the past 4 years, he has worked as part of The Switch Electrical Machines Engineering team allocating internal resources and working on the design of machines and together with customers. Simo is proud to be part of the company’s marine boom with electrical machines over the past few year.