We’re pleased to announce the successful sea trials of our PMM1000M, PMM1500M and PMM2000M designs. These trials validate earlier design simulations and confirm safe cruising and reliable permanent magnet shaft generator operations.

We carried out trials on the Grazyna Gesicka LNG carrier in cooperation with Botnia Engineering, our subcontractor.

Efficient energy design

The Grazyna Gesicka is equipped with solutions that enhance energy efficiency and reduce environmental impact, including a system for integrated management of electricity consumption. The shape of the ship’s hull and the propeller were designed to reduce drag. An air lubrication system (ALS) was included to reduce resistance between the ship’s hull and seawater. In addition, the vessel’s hydrodynamic profile was refined to lower fuel combustion during its operation.

Our PMM1500M fit this modern vessel design well, adding an environmentally friendly solution for efficient electric power generation within a wide range of speeds.

Sea trial procedures

To set up the trials, we first contacted Kaj Rintanen from Botnia Engineering, our subcontractor, for help coordinating the tests. Then we planned all the actions we needed on board and waited for the green flag.

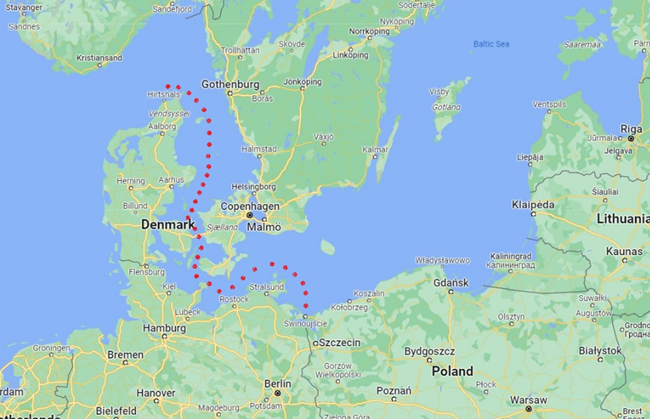

Finally, it came at the beginning of the summer season! We would be joining the vessel for the first part of her return voyage to North America, traveling from Świnoujście, Poland, to the northern tip of Denmark.

We grabbed our backpacks and measurement devices and traveled to Świnoujście. There, the isolated LNG terminal was under high security, with machine gun guards and several checkpoints. How nice to board the vessel at last and meet its nice, kind and cooperative personnel!

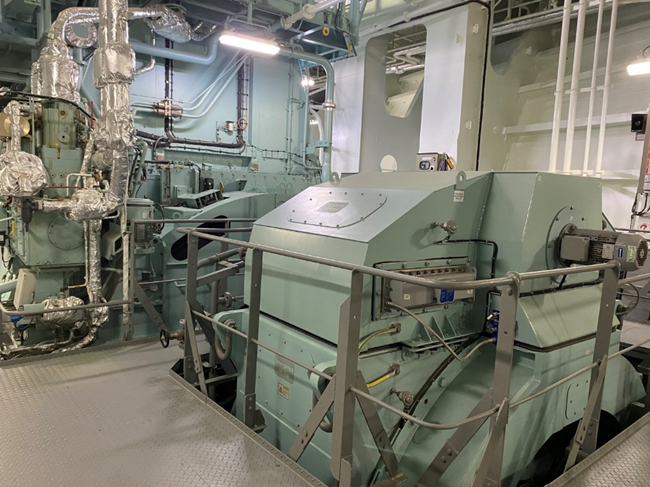

Once on board, we did sanity checks on the engine room and the shaft generator to be measured. This included making safety checks, marking measurement points and building the measurement setup carefully so that no cables, sensors or other equipment could get damaged in that noisy environment with rotating shaft lines, hot surfaces and other potential hazards.

The vessel was newly built and had traveled for only 6 months. Yet, we were pleased to find the vessel environment very clean with sufficient maintenance areas.

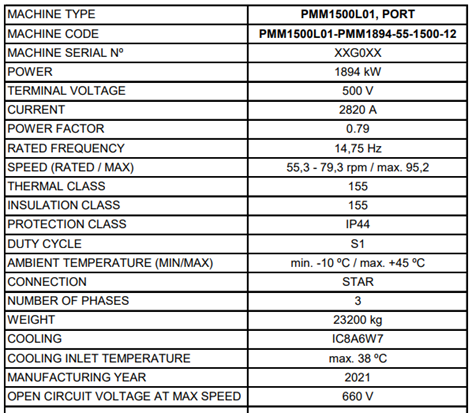

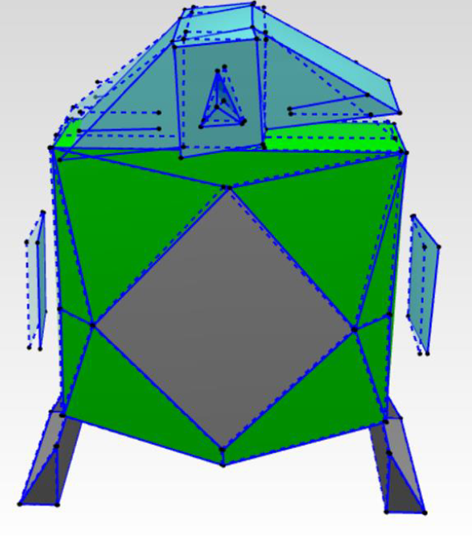

Details of the vessel’s shaft generator are below:

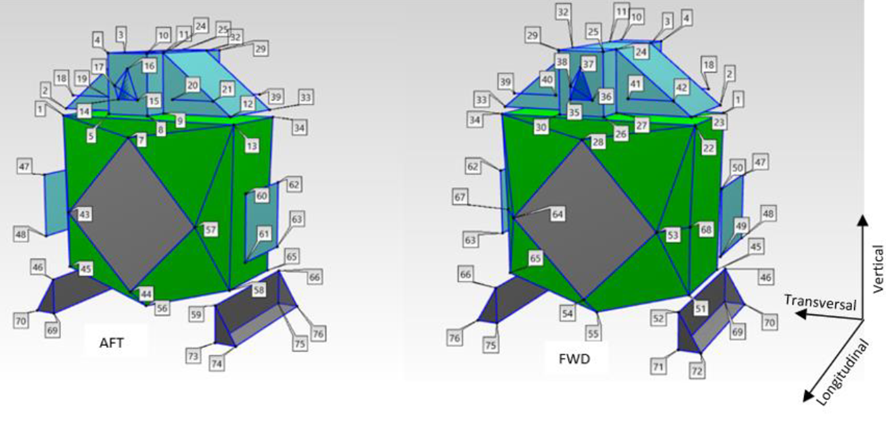

We carried out vibration measurements, including operational deflection shape (ODS) measurements, on the starboard shaft generator at two different shaft speeds, 60 rpm and 71 rpm. In addition, we recorded time signals from fixed points on the generator, representing vibrations during a given time frame.

Once we completed all the measurements, a pilot boat came to pick us up. Stormy weather made our departure a bit rough, but the pilot eventually succeeded in docking next to the Grazyna Gesicka.

Climbing to the pilot boat. Kaj Rintanen already safely on deck.

Once safely aboard the pilot, we started the 45-minute trip to Skagen, Denmark. Some fellow travelers in the tiny pilot boat got seasick, but all recovered after an hour in the harbor.

Riding to shore on the pilot boat. Sometimes it is a bit windy at sea.

Successful results

In conclusion, we found all vibration levels were well within expected levels, with no abnormal behavior detected. This is good news for this ship – and for the tens of others operating in different seas where we have already delivered PMM1500M generators with 12 substacks.

Thanks to my colleagues Erkki Ukkola and Markus Silventoinen for the measurement plan reviews and comments beforehand. And many thanks to Kaj Rintanen for his excellent cooperation and professionalism with everything related to the onboard measurements.

We all look forward to seeing many more shaft generators with our PM machines efficiently providing onboard electricity!

Senior Development Engineer

Simo Mattila

Simo works as Senior Development Engineer at The Switch. He has 15 years of experience in the mechanical engineering of electrical machines. During the past 4 years, he has worked as part of The Switch Electrical Machines Engineering team allocating internal resources and working on the design of machines and together with customers. Simo is proud to be part of the company’s marine boom with electrical machines over the past few year.