The Switch’s approach to building a high-speed machine

In Panu Hava’s previous blog, he discussed the latest technologies and trends in high-speed electric machines in today’s market. In this blog, I would like to describe how The Switch applies these innovations and organizes its processes to successfully build premium electric motors.

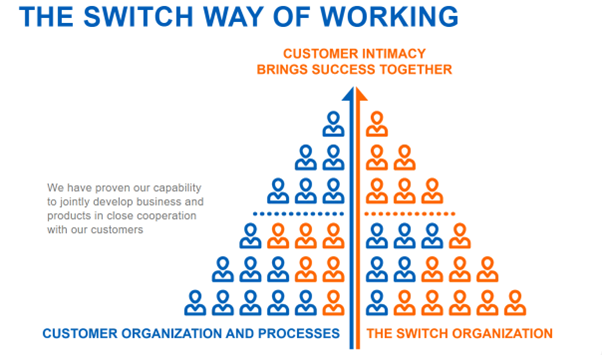

Since its start in 2006, The Switch has grown significantly as an organization, continually improving to better address our customers’ needs and expectations.

From customer contact to feasibility

Before diving into electric machine engineering, we start with thorough discussions with our customers about their specific application. By understanding the application inside out, we can evaluate suitable technologies available in-house or through our partners. This is typically an iterative process that may take months of continuous dialogue before we reach a solution ready for development. Quite often, the work continues with a feasibility study to further define the optimal end-product concept.

Engineering

Adopting the available components and building a complete high-speed machine is not trivial and requires multidisciplinary engineering.

Typical challenges include reaching the maximal circumferential speed of the rotor and squeezing out as much power as possible with good efficiency. These and other issues encountered in solid-rotor machine engineering are described in Jan Barta’s recent article in ScienceDirect.

Tackling such challenges requires seamless cooperation between mechanical, electrical and thermal engineers. Manufacturing and quality engineering are important as well.

In our engineering work, we use simulations across various disciplines, backed up by our experience in testing and verifying similar machines. Once the product definition is finalized, we utilize a phase-gate process to document all details and analyses in our product data management system.

Project Management

Orchestrating in-house engineering requires solid project management, as multiple disciplines and tasks must be coordinated simultaneously.

One key challenge is finding commercially viable options within the supply chain. Here, good communication with suppliers is mandatory, as off-the-shelf solutions are generally unavailable. In addition, the need for high-performance solutions further complicates procurement, adding delays, logistical hurdles and financial strain to the project.

Orchestrating in-house engineering requires solid project management, as multiple disciplines and tasks must be coordinated simultaneously.

One key challenge is finding commercially viable options within the supply chain. Here, good communication with suppliers is mandatory, as off-the-shelf solutions are generally unavailable. In addition, the need for high-performance solutions further complicates procurement, adding delays, logistical hurdles and financial strain to the project.

At the same time, we must still meet customer requirements, match interfaces and keep to schedules. All in all, the operational matrix can become rather complex.

However, at The Switch, we remain highly committed to ensuring smooth project management for all stakeholders in every project. We also remain flexible in defining engineering and delivery responsibilities, which allows us to navigate complex projects efficiently.

From prototype projects to full-scale deliveries, we always collect a technically skilled team, including a project manager and lead engineer, to coordinate the work internally and externally with customers and suppliers.

Quality control

When a rotating machine is designed to challenge existing limits, robust engineering and high-precision components are essential for achieving the targeted performance.

We apply practices such as failure mode and effects analysis (FMEA) and sensitivity analysis to ensure there are no weaknesses in the design. In manufacturing and supplier management, we implement well-structured inspection plans and define clear component requirements and tolerances to control the critical details that really matter.

Assembly and testing

Before delivery, the electric machine must be carefully assembled. Our trained and experienced staff is key to success here.

While the assembly process may be possible with standard workshop equipment, final verification requires a dedicated testing facility. At The Switch, our Large Drive Test Center has the capacity to test electric motors under full load conditions up to 18 MW.

Should we notice any discrepancies during assembly or testing, our Andon system records and evaluates each nonconformity case by case.

By combining the latest technological insights with our deep engineering expertise, proven project management and rigorous quality control, we aim to deliver what our customers want in special machines. With this approach, The Switch is ready to turn today’s possibilities into the next generation of advanced electric drives.

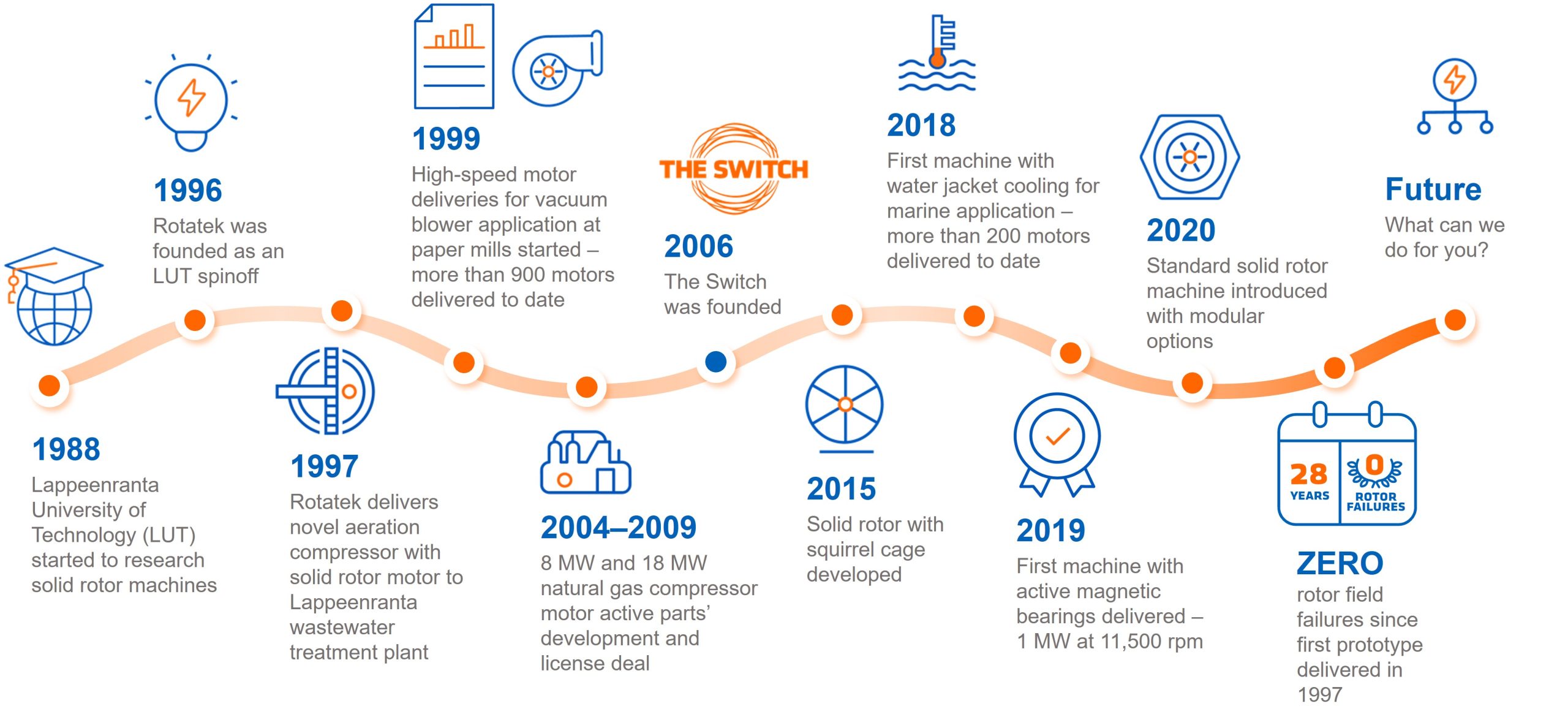

The Switch solid rotor milestones

Mechanical Engineering Manager, Electric Machines

Markus Silventoinen

Markus Silventoinen currently works as Manager for Mechanical Engineering – Electric Machines at The Switch. He has one and half decades of experience in product development of rotating machines, including direct-drive wind and marine PM generators, high-speed electrical machines and gas turbines. Today, his main responsibilities include leading mechanical engineering team, technical sales support for new tailored products and participation in product development of new products. Silventoinen holds a BEng degree in Mechanical Engineering from South Karelian Polytechnic.