|

Jussi Puranen

In today’s emission-conscious world, technology that lowers fuel consumption and, therefore, reduces greenhouse gas emissions is good news.

A study made by Yaskawa Environmental Energy / The Switch during summer 2021 quantified impressive permanent magnet (PM) machine efficiencies for vessels like LNG and LPG carriers that often utilize slow-speed, direct-driven in-line shaft generators producing electrical power from two-stroke main engines.

Growing traction

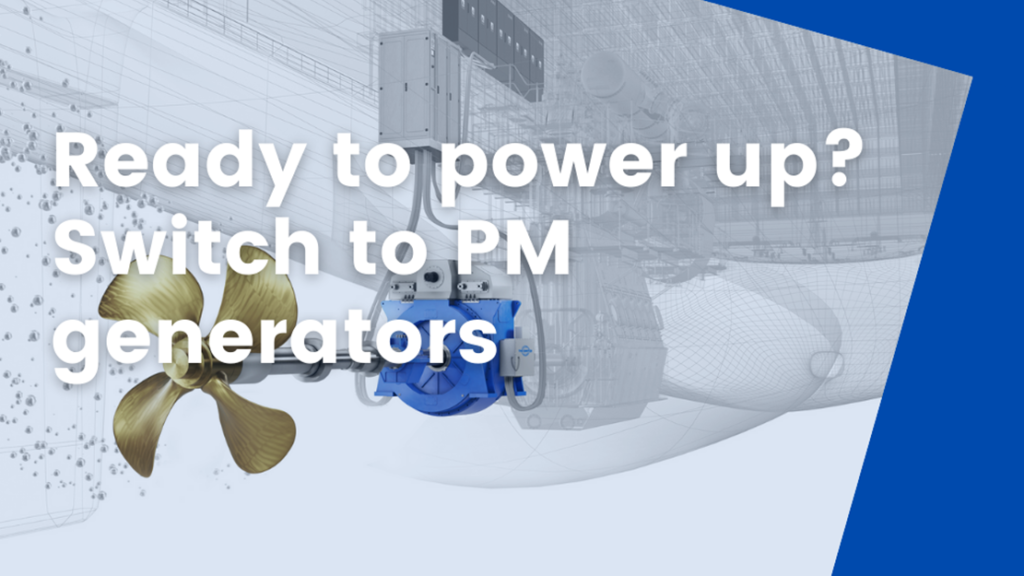

Switching to PM generators takes efficiency to a whole new level – a fact the shipping industry increasingly recognizes.

As of October 2021, we have sold more than 120 direct-drive PM shaft generator systems of various frame sizes and have a growing backlog of orders for large LNG and LPG carriers, among other vessel types.

PMM efficiencies

Comparing efficiency results of an induction machine (IM) and a PM machine in a 1.8 MW converter output system, the study showed the IM required about 23% higher converter current capacity, causing significant electrical losses and the need for a bigger frequency converter. Its full load efficiency was only 92.9% versus 96.1% with the PM machine. There were similar significant differences in efficiency – varying from 3 to 8% units – when operating at partial load.

The IM’s need for constant external magnetization power from the grid, regardless of the load, severely affected the partial load values. In contrast, the PM machine often had peak efficiency at partial load operation.

Significant savings

Let’s look at how these efficiency differences translate into savings in dollars, using the following assumed parameters:

- An average output power of 75% of nominal

- 6,000 annual running hours

- An average 170 g/kWh specific fuel oil consumption (sfoc) for the main engine

- A USD 555 per ton bunker price

When a PM machine is used, the LNG carrier having two propulsion lines, each with a 1.8 MW shaft generator system used in the analysis, would save approximately USD 70,000 per year through lower fuel consumption. A vessel lifecycle of 25 years would capture total fuel savings of close to USD 2 million. Exact savings will naturally depend on operational profile, annual running hours, main engine sfoc and fuel price.

In other words, where slow rotation speeds are desired, using PM technology instead of IMs can significantly improve energy efficiency, lower a vessel’s carbon footprint – and enhance operators’ bottom line through major fuel savings and lower lifetime operating expenses (OPEX).

How PMs make the difference?

So how exactly does the PM machine make a difference?

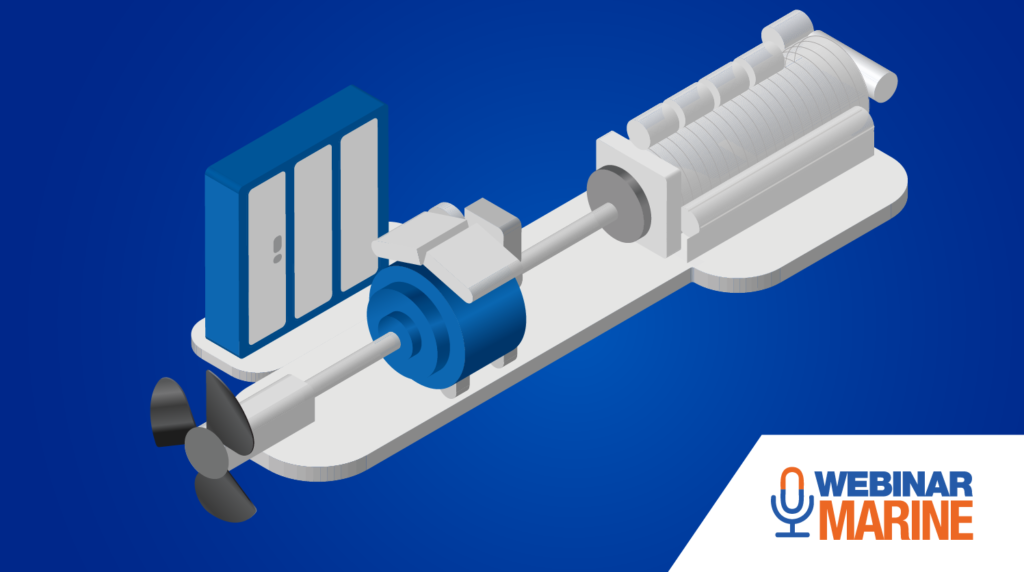

The standard for in-line shaft generators has been electrically excited synchronous generators (EESGs) or sometimes IMs with squirrel-cage rotors. But when efficiency and lower fuel consumption are of prime importance, both have operational drawbacks.

An EESG, whose efficiency lies somewhere between that of a PM machine and an IM, was not included in the study because its characteristics are rather well known already. Its main drawbacks, in addition to lower efficiency, are a more complex mechanical construction, which results in lower reliability and an increased need for maintenance.

The IM’s central drawback is the requirement for constant external magnetization power. This leads to several drawbacks, such as:

- Lower efficiency

- Larger frequency converter due to large magnetization current

- Lower power density to avoid overheating due to higher losses

- Large sized stator and rotor, which increase total weight (and cost)

Now let’s look at how the PM machine compares in this area:

- No need for external energy for magnetization

- No current losses on the rotor

- Power density can be pushed much higher, making PM machines much more compact and lighter

Perfect for slow-speed applications

This is why PM machines are becoming a standard choice in large LNG and LPG carriers using in-line shaft generators. PM technology is the future for power generation in marine!

Please feel free to get in touch with us to discuss your particular needs.

For further specifics of the comparative study results, including electrical and mechanical parameters and all efficiency figures, click here.

About the author

Jussi Puranen

Head of Product Line – Electric Machines

at Yaskawa Environmental Energy / The Switch, Finland

Jussi has nearly 2 decades of experience in R&D and product development of electrical machines, and his main responsibilities are the product management and R&D of electric machines (especially PM machines). Puranen holds an M.Sc. (Technology) degree in Electrical Engineering and a D.Sc. (Technology) degree from the Lappeenranta University of Technology (LUT), Finland.